The Visual Pour: Photography vs. Beverage Product Rendering

The Visual Economy of Beer

The architectural shift in the brewing marketplace is undeniable. The primary point of purchase decision-making has migrated from the tactile environment of the physical shelf to the high-velocity, pixel-dependent ecosystem of the digital scroll. In this environment, your bottle shot is no longer just a supplementary asset; it is a critical component of your digital infrastructure.

For marketing directors and brewery owners, this creates a dilemma. Beer presents a unique "triple threat" of photographic challenges: highly reflective glass or aluminum, refractive liquid contents, and the ephemeral, unstable nature of foam. Historically, conquering these physics required capital-intensive photoshoots. Today, the maturation of beverage product rendering services offers a disruptive alternative—a "Digital Supply Chain" relying on geometry and computational power rather than logistics and chemistry.

This analysis breaks down the granular economic and technical data you need to optimize your visual asset procurement in 2026.

The "Ice and Foam Tax": The True Cost of Traditional Photography

To understand the value of a digital alternative, we must first audit the "Analog Supply Chain." The cost of a professional photoshoot is not merely a reflection of time, but of risk mitigation and specialized labor.

The Hierarchy of Day Rates

Pricing for 2025 shows a sharp bifurcation. While entry-level generalists may charge $350 to $500 per day, they often lack the specialized gear to manage the complex reflections of glass.

For established breweries, the standard is the Mid-Level Commercial Professional, commanding $1,250 to $2,500 per day. For national campaigns requiring hyper-specialized fluid dynamics knowledge, rates soar to $3,500 to $5,500+ per day.

The Hidden Logistics and Material Costs

The "Ice and Foam Tax" refers to the hidden line items required to manipulate a chemically unstable product like beer.

- The Stylist: A competent beverage stylist—essential for engineering the liquid to look appealing—charges $875 to $1,400 per day, often requiring an assistant at an additional $350 to $600.

- Fake Ice & Chemicals: Professional shoots use hand-carved acrylic ice and glycerin mixtures to mimic condensation that won't evaporate. A stylist's "kit fee" for these materials runs $50 to $100 per day.

- Inventory Loss & Shipping: To find one flawless "hero" bottle, a brewery might ship an entire case, incurring shipping fees and product destruction costs as bottles are opened and sprayed with chemicals.

When you tally the photographer, stylist, assistant, studio rental, and retouching, a single high-end production day can easily exceed $7,000 to $12,000.

Beverage Product Rendering Services: The Digital Supply Chain

3D rendering shifts expenditure from service-based Operational Expenditure (OPEX) to asset-based Capital Expenditure (CAPEX). You aren't paying for a moment in time; you are paying for a "Digital Twin"—a non-destructive asset capable of infinite reconfiguration.

The Asset Creation Economy

The primary cost in beverage product rendering services is the initial modeling.

- Low Complexity ($275 - $400): Standard aluminum cans or longneck bottles. These are geometrically simple and require less modeling time.

- High Complexity ($1,000+): Custom-molded glass, heavy embossing, or complex fluid simulations.

The "Label Swap" Advantage

The decisive economic advantage for craft beer lies in the Marginal Cost of Variants. Once a "Master Scene" is created (e.g., a cold can with perfect condensation), applying a new label for a seasonal release is a trivial task.

- The Savings: Studios typically charge $30–$50 per product to swap the digital label and re-render.

- The Comparison: To achieve this photographically, you would need to reship product, re-book a photographer, and re-light the scene. The 3D workflow offers a 90% cost reduction for seasonal releases.

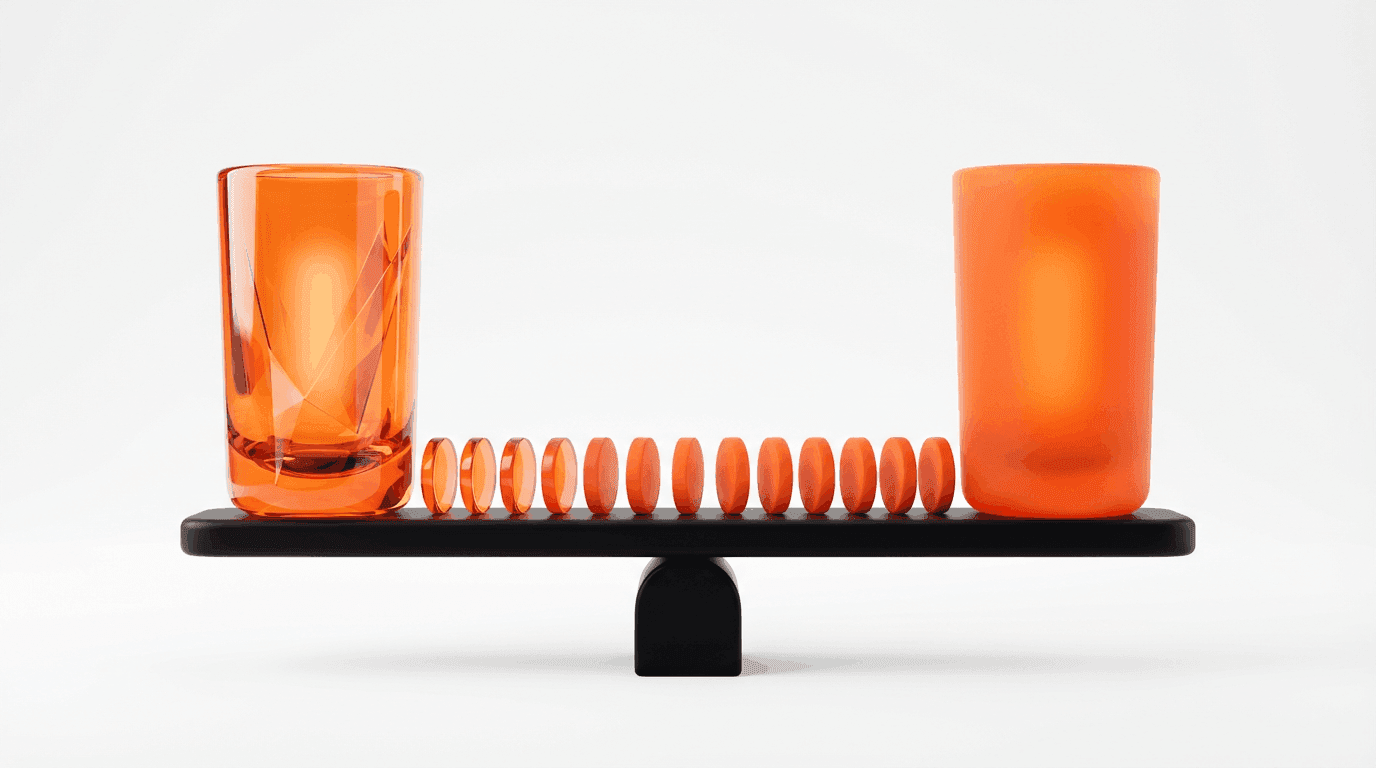

Technical Analysis: Physics and Friction

While economics favor digital, quality is paramount.

The Uncanny Valley of Foam

Foam is the holy grail. Photographically, a camera captures the chaotic, organic reality of bubbles instantly. In 3D, simulating this involves complex particle systems. Poorly executed renders often suffer from the "Uncanny Valley" effect, where foam looks like solid styrofoam. However, high-end rendering engines are closing this gap with advanced Sub-Surface Scattering (SSS) shaders.

Speed: Decoupling Visuals from Manufacturing

Traditional photography is linearly dependent on the physical supply chain: you cannot shoot the can until it is printed, filled, and seamed. This often means marketing assets arrive 1-2 weeks after the beer is ready.

Beverage product rendering services decouple this process. Using just the label art file, rendering can happen concurrently with brewing. Breweries can launch pre-orders and populate distributor sales sheets weeks before the beer is even packaged.

Why HoppyShots is the Superior Choice

At HoppyShots, we have optimized the "Digital Supply Chain" to eliminate the friction of traditional rendering and the high costs of photography. We combine the fidelity of high-end specialized rendering with the speed of AI-enhanced workflows to deliver the perfect pour.

1. Cheaper: Zero Logistics, Zero Waste

We eliminate the "Ice and Foam Tax" entirely.

- No Shipping: Forget about wrapping glass bottles in bubble wrap and paying for expedited shipping. We work from your digital label files.

- No Crew Costs: We don't charge day rates for stylists, assistants, or studio rentals. You pay for the final asset, not the hours on set.

- Sustainability: By eliminating physical shipping and travel, our virtual production reduces carbon emissions by 75% to 90% compared to location shoots.

2. Faster: Market Your Beer Before You Brew It

Speed is a competitive advantage. With HoppyShots, you don't wait for the canning line.

- Concurrent Production: Send us your label art while the beer is still in the tank.

- Instant Turnaround: We bypass the 3-7 day turnaround of freelance artists and the logistics of shipping. Get your assets in time for your "Coming Soon" campaign.

3. Better: The Perfect Pour, Every Time

We solve the "Uncanny Valley" through specialized, pre-simulated liquid assets.

- Digital Control: We offer procedurally generated condensation that is geometrically perfect, ensuring droplets never obscure your logo—control that physical spray bottles can't match.

- Brand Consistency: We create a "Digital Twin" of your brand. Your brand red will be hex-code correct in every image, across every season, forever.

The Bottom Line

For breweries managing high SKU counts and aggressive seasonal calendars, the choice is clear. Traditional photography relies on a physical chain that is slow, expensive, and wasteful. HoppyShots offers a scalable, sustainable, and economically superior solution.